News - NEA POWDER COATING NEWS

Climate change in powder coating production

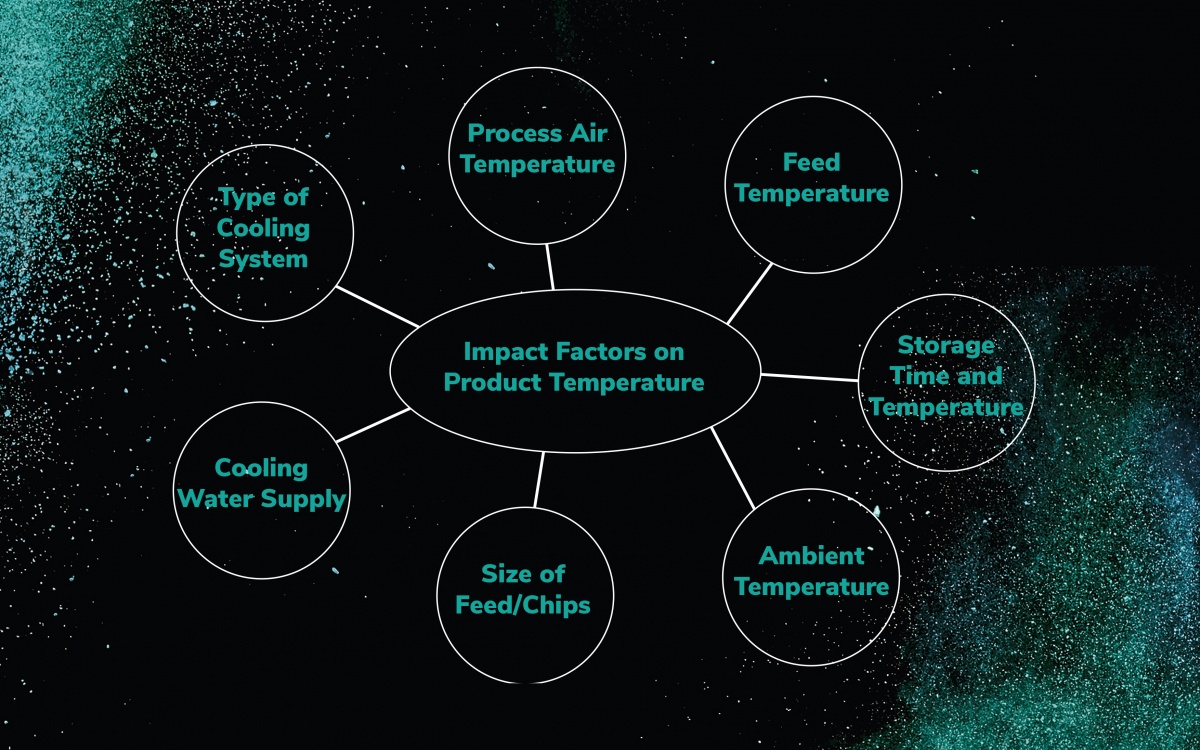

The increasing temperatures during the warm months with new heat records around the world, present more and more challenges for Powder Coating manufacturers. The increasing complexity of today’s modern powder coatings recipes require increased quality standards in the powder coating production. Temperature and humidity, as the determining factors, influence the production in all steps of the process, starting from storage of the raw materials and ending with the boxing and even distribution of the final product. Therefore, not only the product temperature itself, but also factors like the storage time at ambient temperatures and humidity between the different processing steps need to be considered.

Effect on mill performance

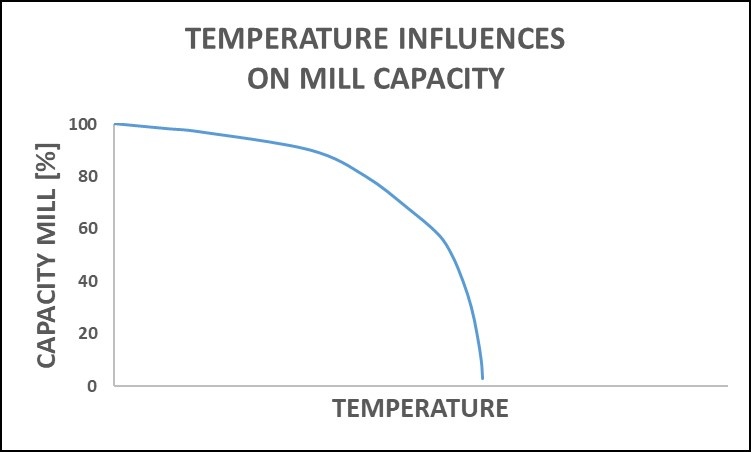

Besides transporting the material within the system, the process air is mainly responsible for removing the grinding energy (heat) out of the system. The more material is fed to the mill, the harder the mill must work, and consequently, the internal system temperature increases. Because of this, the initial mill inlet temperature is an essential factor for the maximum possible throughput of the mill. A common value for the inlet temperature in this industry is 11°C (52°F). Even a slight increase of a few degrees can have a major negative impact on the grinding capability of the feed product as the chips become softer. As a result, the maximum possible capacity of the grinding system can decrease by up to 30-40%

Improvement of cleaning

If the product temperature gets close to its Tg point, the powder will start building up on the inner surfaces of mill, the ductwork and the cyclone. Once this process starts, it effects the mill performance, the yield and increases the risk of contamination between batches. Once significant build-up has occurred, the system needs a deep cleaning, which could take several hours. Experience has shown that some of these layers can only be efficiently removed by physical treatments such as dry ice blasting.

Efficient Cooling

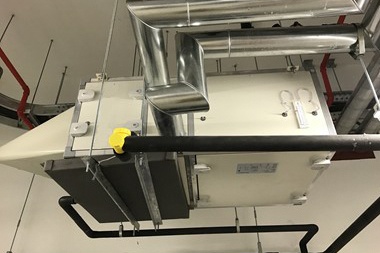

In particularly warm regions, the installed water-air cooling solutions are often not sufficient to ensure the required low intake temperatures during high temperature periods. A popular method of counteracting this is to inject nitrogen into the grinding chamber. However, this easily becomes very costly when compared to a adequately sized water-air cooling solution. As an example, a factory with a production rate of 1,000,000 kg/month and a nitrogen consumption of 300 m³/month spends 120,000€/month in nitrogen, considering cost of 0.40 €/liter. This adds cost of 12 Euro Cents per kg of powder. Besides the cost, safely handling such volumes of Nitrogen can be a challenge. A properly designed water-based cooling system provides a much safer and economical solution. Secondly, as already mentioned above, the air humidity is another important parameter to be watched. New hydroscopic powder coating formulas require a precisely controlled air humidity, which older cooling systems cannot provide. For these reasons, sophisticated cooling and drying units have gained entry in the powder coating industry.

NEUMAN & ESSER is frequently doing observations of grinding systems in the powder coating industry worldwide. The experience drawn from these observations over the years helped to understand the specific needs of the customers and clearly shows that the requirements are changing. Efficiency, availability and certainly safety become more and more important and help being competitive in a tough market.

NEA Process Technology always strives to keep pace with the global developments in all market segments. As an OEM of ICM grinding systems in the powder coating industry, we use our expertise to provide superior solutions, that fit the specific demands of our customers.

Jonas Appeltrath

Sales After Market

+49-2451-481-229

jonas.appeltrath_at_neuman-esser.de

NEUMAN & ESSER Process Technology

Werkstr. o. Nr. , 52531 Übach-Palenberg